The Ultimate Guide To Door Infill Panel

Table of ContentsEverything about Door Infill Panel5 Easy Facts About Door Infill Panel ShownDoor Infill Panel Can Be Fun For Anyone

Aluminium composite material panel framework A sandwich panel is any structure made of 3 layers: a low-density core, and also a slim skin-layer bound per side. Sandwich panels are used in applications where a combination of high structural rigidness and low weight is called for. The architectural capability of a sandwich panel is similar to the classic I-beam, where two face sheets largely stand up to the in-plane as well as side bending tons (comparable to flanges of an I- beam), while the core material mostly withstands the shear tons (comparable to the internet of an I-beam). The suggestion is to utilize a light/soft but thick layer for the core as well as solid but thin layers for face sheets.

They appear in commercial and workplace structures, in tidy and cold areas and additionally in private houses, whether restoration or new-build. They integrate a premium product with high versatility regarding design. They usually have an excellent energy-efficiency and also sustainability. In product packaging, applications consist of fluted polypropylene boards as well as polypropylene honeycomb boards. Due to the ability of 3D printers to fabricate complicated sandwich panels there has just recently been a prospering of research study in this field covering energy absorption, natural fiber, with constant artificial fibers, and for vibration. The assurance of this technology is for new geometric complexities in sandwich panels not feasible with various other construction processes.

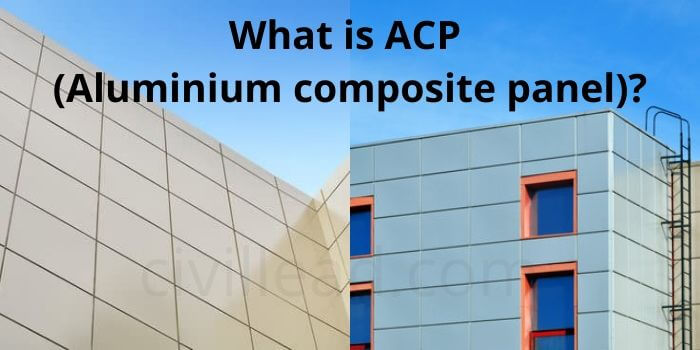

Building and construction website panel made from aluminium composite material (Dibond) Detail view of building website panel Aluminium composite panels (ACP), made of aluminium composite material (ACM), are level panels containing two thin coil-coated aluminium sheets bonded to a non-aluminium core. ACPs are often made use of for exterior cladding or facades of buildings, insulation, and signage - door infill panel. ACP is generally used for exterior and internal architectural cladding or dividers, incorrect ceilings, signage, machine treatments, container building and construction, and so on. Applications of ACP are not restricted to external building cladding, but can additionally be used in any type of cladding such as dividings, false ceilings, etc.

Not known Factual Statements About Door Infill Panel

ACP has actually been made use of as a light-weight but really strong product in building and construction, especially for transient structures like trade convention booths as well as comparable short-term elements. It has actually recently also been taken on as a support product for placing art digital photography, usually with an acrylic coating using processes like Diasec or other face-mounting methods. ACP material has actually been used in well-known frameworks as Spacecraf Earth, Van, Dusen Botanical Garden, the Leipzig branch of the German National Library. These frameworks made ideal use ACP with its cost, durability, and effectiveness. Its flexibility, reduced weight, and very easy creating as well as processing permit cutting-edge style with raised strength and sturdiness.

The standard ACP core is polyethylene (PE) or polyurethane (PU). These products do not have great fireproof (FR) residential or commercial properties unless particularly treated and also are as a result not typically appropriate as a building product for homes; several jurisdictions have actually prohibited their usage entirely. Arconic, proprietor of the Reynobond brand name, cautions the potential buyer. Worrying the core, it states that range of the panel from the ground is a component of "which materials are more secure to make use of". In a sales brochure it has a graphic of a building in fires, with the inscription" [a] s quickly as the structure is greater than the firefighters' ladders, it needs to be conceived with a fireproof material".

70% mineral core) from there to approximately c. 30 meters, the height of the ladder; and also the European A2-rated product (c. 90% mineral core) for anything over that. In this pamphlet, Fire Safety in High-rise Structures: Our Fire Solutions, item specification is just given for the last two products. The cladding products, specifically the core, have actually been linked as a feasible useful link contributing consider the 2017 Grenfell Tower fire in London, as well as in skyscraper fires in Melbourne, Australia; France; the United Arab Emirates; South Korea; and the USA. Fire-rated cores, such as mineral wool (MW), are an alternative, however are typically a lot more costly and usually not a lawful need.

Aluminium can be repainted in any type of colour, and ACPs are created in a vast array of metal as well as non-metallic colours along with patterns that imitate other materials, such as timber or marble. The core is commonly low-density polyethylene (PE), or a mix of low-density polyethylene and also mineral product to show fire retardant properties. 3A Compounds (previously Alcan Composites & Alusuisse) developed aluminium compounds in 1964 - as a joint invention with BASF- as well as commercial production of Alucobond commenced in 1969. The product was patented in 1971, a license which ran out in 1991. After the expiry of the license several companies began business manufacturing such as Reynobond (1991 ), Alpolic (Mitsubishi Chemicals, 1995), etalbond (1995 ).

Fascination About Door Infill Panel

Sandwich panel construction strategies have experienced significant development in the last 40 years. Formerly, sandwich panels were thought about products suitable just for useful building and constructions and commercial buildings. Nonetheless, their excellent insulation features, their adaptability, high quality as well as appealing visual appearance, have actually caused an expanding and also extensive use the panels throughout a significant range of structures. door infill panel. Sandwich panels require the CE mark to be marketed in Europe. The European sandwich panel requirement is EN14509:2013 Self-supporting double-skin metal-faced official site insulating-panels - Factory-made products Requirements. Sandwich panels quality can be certified by using the high go to the website quality level EPAQ The qualities that have generated the quick growth in the usage of sandwich panels, specifically in construction, include: Sandwich panels have -values from 0.